Large water -cooled/frozen water type precision air conditioner

The Yingweiteng Weiyang VCA series of precision air conditioners for refrigerated IDC rooms are end temperature control products that provide internal environmental temperature, humidity, and cleanliness control for scenarios such as IDC rooms, communication rooms, and equipment rooms.

Classification:

Room air conditioner

Product Description

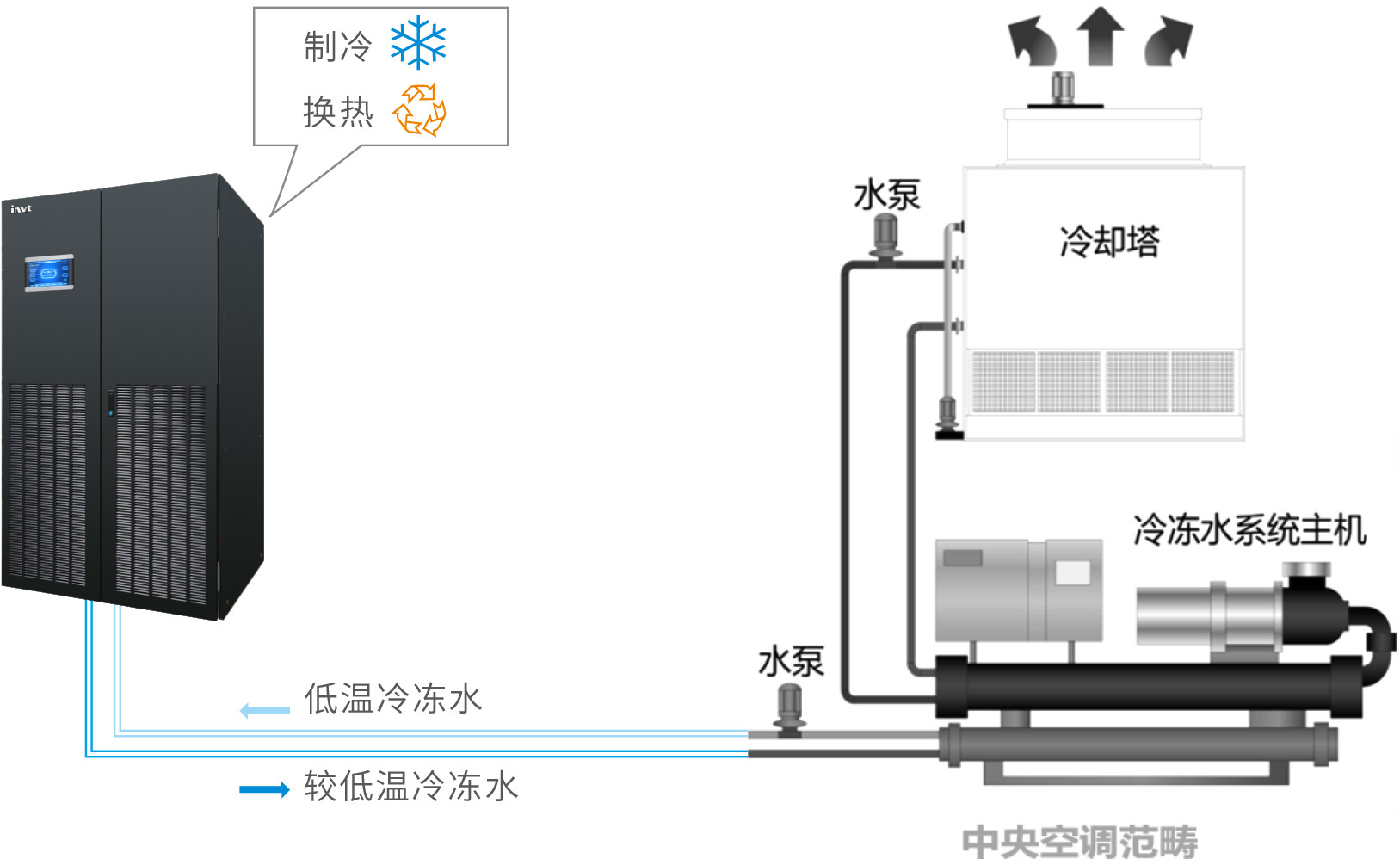

The Yingweiteng Weiyang VCA series of precision air conditioners for refrigerated IDC rooms are end temperature control products that provide internal environmental temperature, humidity, and cleanliness control for scenarios such as IDC rooms, communication rooms, and equipment rooms. They are usually combined with cooling towers, chillers, pumps, and refrigeration pipelines to form a refrigeration system, ensuring that cabinet equipment, server equipment, industrial process equipment, communication equipment, UPS power supply, distribution equipment, etc Batteries and other devices have a reasonable temperature and humidity operating environment.

Primary

Performance characteristics

Energy efficient

✓ Design of heat capacity, enthalpy difference, and sensible heat to meet the temperature control requirements of the computer room;

✓ Effective rear tilt EC separation machine, adjusting the speed based on real-time thermal load to maximize energy saving;

✓ Adopting a V/A type surface cooler with better flow organization and significantly improved heat exchange efficiency;

✓ Internationally renowned brand electric pumps with flow control valves for flow control and dynamic matching of thermal load;

✓ Internal pipelines are made of corrosion-resistant copper pipes, and welding design is adopted between pipelines to reduce the risk of leakage.

Safe and reliable

✓ Adopting strictly certified high-quality devices to improve reliability from the source;

✓ The product has undergone rigorous and repeated testing and verification, meeting standard requirements, and delivering high-quality products;

✓ 365 × 24/7 uninterrupted operation, designed for a long service life and low maintenance costs;

✓ Intelligent monitoring of air conditioning power supply voltage, power frequency, and three-phase imbalance;

✓ Dual electronic control box design, strong and weak current isolation, to avoid signal interference。

Intelligent control

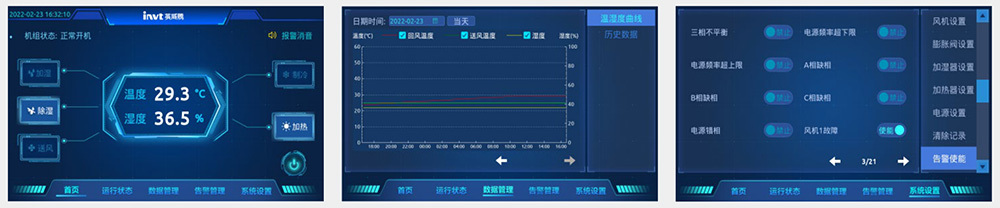

✓ 10 inch full color capacitive touch screen, multi-level password permissions, expert system inspection and diagnosis function, more intelligent;

✓ Fully monitor and display various display modes for air conditioning capacity, cooling capacity, graphic status, and temperature and humidity curves;

✓ Up to 64 air conditioning rotation groups, achieving timed rotation, fault rotation, cascading, demand synchronization, anti-competitive operation, etc;

✓ With functions such as holding an incoming call, starting, timing on/off, etc., it is convenient to manage the air conditioning;

✓ Local ultra fast storage, with over 2000 historical records for easy viewing and tracing;

✓ Standard RS485 connection, optional SNMP connection.

Flexible configuration

✓ Various feeding methods such as downward feeding, upward feeding on the tube, and forward feeding on the cap are available;

✓ Designed with a pull-out electronic control box, it is convenient for on-site maintenance and saves time and energy;

✓ Modular frame structure, requiring cutting of pipelines for easy on-site handling during disassembly and assembly;

✓ Equipped with multiple remote temperature and humidity sensors;

✓ Equipped with optional leak detectors

Technical Data Sheet

| Model | Unit | VCA030 | VCA040 | VCA050 | VCA060 | VCA070 | VCA080 | VCA090 |

| Total cold | kW | 32.8 | 44.0 | 50.2 | 63.2 | 73.0 | 85.0 | 94.7 |

| Cooling amount | kW | 32.8 | 44.0 | 50.2 | 63.2 | 73.0 | 85.0 | 94.7 |

| Air volume | m3/h | 9500 | 11000 | 12000 | 14000 | 15000 | 20000 | 21500 |

| Rehears the calories | kW | 6 | 6 | 6 | 9 | 9 | 9 | 9 |

| Humidity | kg/h | 5 | 5 | 5 | 10 | 10 | 10 | 10 |

| Number of fans | - | 1 | 1 | 1 | 1 | 1 | 2 | 2 |

| Fan type | EC rear fugitive fans | |||||||

| Power supply | 380VAC/50Hz/60Hz | |||||||

| Water flow | m3/h | 5.8 | 7.8 | 8.9 | 11.2 | 12.9 | 15.0 | 17.2 |

| Hydraulic drop | kPa | 45 | 50 | 60 | 60 | 65 | 70 | 70 |

| Inlet and out of water pipe diameter | mm | 32 | 32 | 32 | 42 | 42 | 42 | 42 |

| Full load current | A | 25 | 30 | 30 | 33 | 33 | 47 | 47 |

| Size (W*D*H) | mm | 900*995*1975 | 900*995*1975 | 900*995*1975 | 1100*995*1975 | 1100*995*1975 | 1800*995*1975 | 1800*995*1975 |

| Weight | kg | 320 | 325 | 350 | 370 | 370 | 470 | 470 |

| Model | Unit | VCA100 | VCA110 | VCA120 | VCA130 | VCA140 | VCA150 |

| Total cold | kW | 105.3 | 112.0 | 121.6 | 132.1 | 143.0 | 152.0 |

| Cooling amount | kW | 105.3 | 112.0 | 121.6 | 132.1 | 143.0 | 152.0 |

| Air volume | m3/h | 24000 | 25000 | 26000 | 30000 | 32000 | 34500 |

| Rehears the calories | kW | 9 | 9 | 12 | 12 | 12 | 12 |

| Humidity | kg/h | 10 | 10 | 10 | 10 | 10 | 10 |

| Number of fans | - | 2 | 2 | 2 | 2 | 2 | 2 |

| Fan type | EC rear fugitive fans | ||||||

| Power supply | 380VAC/50Hz/60Hz | ||||||

| Water flow | m3/h | 18.6 | 19.8 | 22.6 | 25.1 | 27.1 | 27.9 |

| Hydraulic drop | kPa | 62 | 68 | 72 | 77 | 82 | 85 |

| Inlet and out of water pipe diameter | mm | 54 | 54 | 54 | 54 | 54 | 54 |

| Full load current | A | 50 | 50 | 50 | 50 | 50 | 50 |

| Size (W*D*H) | mm | 1800*995*1975 | 1800*995*1975 | 2200*995*1975 | 2200*995*1975 | 2200*995*1975 | 2200*995*1975 |

| Weight | kg | 600 | 650 | 690 | 690 | 880 | 880 |

Remarks:

The performance parameters in the above table are based on indoor return temperature of 28 ℃, relative humidity of 40%, and inlet/outlet temperature of 10/15 ℃.

2. The upward feeding unit adopts two different outlet modes: vertical top feeding (in conjunction with on-site pipe feeding) and forward feeding.

3. The forward delivery method can include adding a forward delivery cap (with an increase in height) or a standard forward delivery cap (with a prefabricated outlet) on site.

4. In order to save machine losses and achieve efficient cooling, the standard product of the air conditioning system for the lower air supply is the machine sinking type, and it is recommended that the static electricity floor thickness be ≥ 400mm.

5. In case of special circumstances on site, the air conditioning system can be customized and equipped with a partially sunken air conditioner.

6. The air conditioning models listed in the above table are all basic models, and the specific shipping models should be based on the actual situation.

If you have any other customized requirements or technical parameters not listed in the table, please feel free to contact our company in a timely manner.